How do I increase my rate of fire? This is a fairly easy question to answer, so we will go over some basic ways to increase your AEG’s rate of fire. Rate of fire hinges upon several aspects: Motor, gear ratio, battery, gearbox efficiency, and your gearbox load. So depending on what kind of rate of fire you are looking for your set up will vary. If you would just like 25 BPS, for example you may only need a high speed/ high torque motor and a LiPo. Airsoft has evolved to an era in which the high 20s a second is considered slow or ‘the norm’ amongst most techs. Many users are boasting guns up to 60 plus BBs per second.

So let’s start off by going over the basics.

MOTOR: Motors for AEGs are classified into three basic types: high torque, high speed, and a mixture of speed and torque. Getting a quality aftermarket motor will most certainly be necessary when building your high speed gun. Torque motors are usually used on specialty high speed builds, usually guns that are pulling springs above 120 m/s or dual sector gear builds. Torque motors utilize strong magnets and will gain speed much quicker than high speed motors will. They are also more powerful motors, overall. High speed motors have their benefits as well; they are to be used with springs of a lower rating, usually no greater than M110 or equivalent. Speed motors take a longer time to achieve their maximum speed, however once that maximum speed is reached, they will spin quicker than torque motors. This is under the assumption that they are not under the load of a heavy spring. Remember they are best suited to be used with less strenuous springs.

GEARS & RATIOS: Most Marui spec AEGs come with a gear ratio of approximately 18:1, which is used as the standard. Anything less than 18 is considered high speed, and anything over is considered to be torque. If you are looking to build a high speed gun, with a rate of fire of 25 RPS more or less. Your gears may not need changed. But on the subject of high RoF builds, it is wise to shoot for a gear ratio of 14:1 or less. Why? Because 16.:1 is hardly any different than standard (18:1). Combining both higher speed gears with a high torque/speed motor will get you very noticeable results by themselves.

Specially Built Sector Gears: Some users prefer to have mega-high speed. This calls for a dramatic change in gear operation, using the dual sector gear. Sector gears have 16 piston contact teeth. The dual sector gear divides the teeth up, putting 8 on opposite sides of each other. This results in two piston cycles for each sector revolution, which can double your rate of fire. The dual sector gear is not intended for inexperienced techs or users lacking tech experience. Unless you have the necessary experience, you probably can’t handle the demands and modifications to make the dual sector gear work properly.

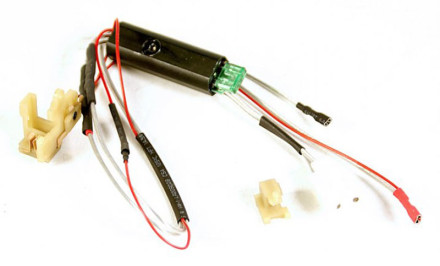

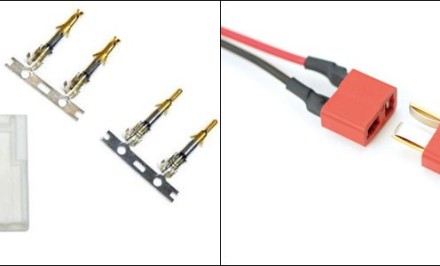

BATTERY: Higher voltage increases motor speed and torque. Most widely used battery for high speed builds is an 11.1 v LiPo. 15 C + — A Higher discharge rate is usually necessary in high speed builds pulling back a heavy load. As mentioned in the Batteries 101 article, you should utilize a MOSFET switch to protect your AEG from higher voltage batteries such as 11.1 Volts or higher.

GEARBOX EFFICIENCY: To achieve the full advantage of your AEGs RoF, or to maximize its potential. You will need to make sure your mechbox is in top condition so it will not be slowed down. You will want to make sure your gearbox is shimmed properly with the shim space you have available. Poorly shimming your gearbox will put more stress on your motor and your gears, RoF and trigger response will suffer, and make your reduce the life span of your AEG, especially if you are using high speed components. Take your time shimming and do a good job.

If the AEG does not have decent bushings or ball bearings you will need to purchase some. Ball Bearing bushings are the preferred method for high speed builds because there is less friction on the gear axels, however the bearings can explode during super high speed possibly leading to more serious issues in your gearbox. Solid steel bushings will be more stable, but will usually not spin as well as ball bearings.

Lightening the piston – also known as “Swiss cheesing” – is highly recommended, along with utilizing a light weight piston head (POM) to keep weight down.

Correction of the Angle of Engagement (AoE) is also required. Most experienced users are familiar with this. If you are not, then refer back to our Angle of Engagement article. The preferred method is through use of a Sorbothane pad with protective pad(s).

GEARBOX LOAD: This is more of a subcategory of the previous category. The heavier the spring used in your AEG, the harder your motor has to work to pull it back, which draws more amps. Generally, the less load the better the motor can do its job and spin. Think of it aspects of automotive mechanics. You have two identical cars, both engines produce 500 horsepower and the exact same torque figures. However one car is carrying an additional load of 800 pounds. The car that weighs less will accelerate more quickly and have a higher top speed. The same principles apply with spring weight; the heavier the spring, the slower the rate of fire. Some short stroked builds and all dual sector gear builds require a heavy spring or buffered spring to compensate for the FPS loss as the piston is not being pulled back as far.